Platforms

INSA Centre Val de Loire has 11 platforms that are used for research purposes but are also made available to companies through various forms of partnership.

BLOIS CAMPUS

The INSA Blois campus is distinguished by its six innovative research platforms, which promote interdisciplinarity and scientific excellence. These state-of-the-art infrastructures offer students and researchers an environment conducive to experimentation and collaboration. Thanks to these resources, the campus is asserting itself as a key player in the field of research and technological development.

The aeraulics/hydraulics platform with the LaMé, which includes:

- a hydraulic circuit to characterise pumps (alone, in series and in parallel), regular and singular pressure losses, through different types of valves, and to characterise cavitation (diameter of 304 stainless steel hydraulic line: 80 mm)

- a return circuit subsonic wind tunnel with two test sections: one for turbines measuring 1.4m x 1.4m with a maximum speed of 15m/s, and one for faster tests, up to 60m/s with a cross-sectional area of 0.7m x 0.7m, with aerodynamic balance (3 forces & 3 moments)

- an Eiffel-type open return wind tunnel with a test section measuring 0.2m x 0.3m

- a wake-rake wind tunnel for characterising jets, the Coanda effect and the fan

- an aeraulic circuit with a centrifugal fan to characterise the aeraulic control elements

Thermo-mechanical characterisation and modelling of materials in the quasi-static regime with the LaMé: Physico-chemical characterisation of polymers, composites and nanocomposites.

Models are developed for structural calculations and then characterised through test campaigns. The use of digitally-controlled machines makes it easy to create dedicated assemblies for specific tests.

- 3 test machines: 2 quasi-static (1T and 3T) and 1 dynamic (10T), with a gripping system and various cells.

- Software: TWE (MTS) and Wavemaker (Instron)

- 1 pressure unit (320 bar) + containment vessels (160 bar): miscellaneous equipment

- Gauge extensometer, bi-axial video extensometer and linear variable differential transformer (LVDT).

- Temperature chamber(-40°C - 220°C)

- Acquisition systems

- Air-conditioned test room

The LaMé experimental vibration analysis laboratory has a wide range of test facilities for investigating the dynamic behaviour of fixed and rotating structures, including:

- 2200N LDS V650 shaker+ m+p closed-loop control system for monitoring and regulation

- Several shakers: 440N, 200N, 120N and 2*10N

- Several impact hammers(from 200N to 2200N)

- Several professional open-loop acquisition systems: BK Connect (8 channels) DEWESOFT (20 interlinked channels), LMS (8 channels) m+p (4 channels)

- Two closed-loop acquisition systems (regulation): Amtechdata (2 channels) and m+p (4 channels)

These resources enable the team to carry out experimental and operational modal analyses, vibration monitoring and diagnostics, as well as vibration fatigue on complex industrial structures and systems. The complementary nature of these 3 LaMé platforms enables the team to conduct cross-disciplinary projects and respond to specific needs.

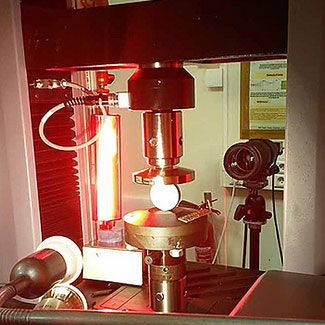

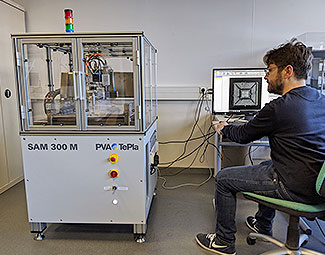

The research activities associated with this platform concern the ultrasonic characterisation of complex materials and piezoelectric applications, from modelling (analytical and digital) and characterising ultrasonic transducers to energy harvesting devices. The platform’s main equipment includes:

- Instrumentation for non-destructive ultrasonic testing (linear and non-linear): motorised characterisation bench (immersion and aerial), generators, oscilloscope, spectrum analysers, transducers from kHz to 50 MHz (immersion, contact, aerial, etc.), multi-elements probe, shakers

- Optical measurement equipment (laser and confocal interferometers) for non-contact deformation measurements in opaque and transparent media

- A high-frequency acoustic microscope for the characterisation of microsystems

- This equipment is complemented by other resources for measuring the properties of evolving materials, such as an ultrasonically instrumented rheometer for polymers

The teams are able to characterise piezoelectric materials and devices using electrical measurements (network analyser, impedance measurements, etc.) or optical measurements (in particular laser measurement systems adapted to micro-devices: probe station).

Vibratory excitation systems combined with optical and electrical measurement equipment are used to characterise and study piezoelectric energy harvesting (by compression or vibration).

INSA Centre Val de Loire has a materials science technology platform in partnership with the Blois University Institute of Technology.

The two institutions have pooled their human expertise (research engineers, research professors, teachers and technicians) and their technological resources (testing, qualification, characterisation, simulations, CAD/CAM, etc.) to support companies in their development and innovation initiatives, and to assert the region’s expertise in the cutting-edge field of materials science. Companies using this platform require skills in the following areas:

- the design and production of plastic and composite parts

- the design and production of tooling parts

- the use of plastics, metals, rubber, composites and ceramics

- the physico-chemical, structural, microstructural and mechanical characterisation of materials

- the design and carrying out of customised tests

The School of Nature and Landscape and researchers from the CITERES laboratory have also developed a workshop site integrated into the “Urban Environments” platform of the Loire Workshop Zone, a research infrastructure of the INEE (CNRS). This workshop site enables interdisciplinary research to be developed in order to understand the interactions between urban uses, planning and management practices and ecological processes (the response of plants and pollinators to artificialisation and urban morphologies, perceptions of ecological spontaneity and changes in practices, urban planning and flood risk, etc.).

It is open to researchers from all disciplines, mainly academics, but also to other stakeholders in the region (administrators, developers, politicians, etc.).

Le laboratoire LaMé dispose de nombreux moyens d’essais pour élaborer et caractériser les propriétés physiques et mécaniques des polymères comme :

Un spectrophotomètre UV-Visible proche IR (JASCO V-770) avec double faisceau et double monochromateur permet des mesures avec des échantillons de faibles concentrations de 190 à 2700 nm.

Un analyseur thermique simultané (STA 6000) permet de mesurer la stabilité thermique des matériaux et analyser leur réactivité ou composition pour un plage de température 15 °C - 1000 °C.

Un spectromètre FTIR Nicolet iS50 (Thermo Scientific) équipé une double source (IR Polaris Longue durée et lumière blanche tungstène-halogène) permet de caractériser de matériaux avec une flexibilité et de bonnes performances (avec transmission et réflexion).

Un analyseur mécanique dynamique en température (DMTA) (ElectroForce DMA 3200) permet de mesurer la propriété viscoélastique de matériaux en traction, compression et flexion de -85 °C (chiller triple étage) à 500 °C. Cette machine dynamique électro-pulsée est également une machine de fatigue qui permet de solliciter des échantillons jusqu’à une fréquence de 300 Hz. Deux capteurs d’efforts (500 N et 22 N) sont disponibles.

Une presse à plateaux chauffants (SCAMEX) de 20 T, munie de plateaux 300 mm x 300 mm, permet d’élaborer des échantillons de polymères chargés et de composites. La plage de température disponible est de 20 °C à 350 °C.

Un mélangeur interne équipé de deux chambres de capacité respectives de 40 cc et 300 cc.

Une balance avec une précision avec une résolution de 10 microgrammes.

Un four de trempe, un four de revenu, et une étuve à vide avec pompe à vide servo-régulée.

BOURGES CAMPUS

The INSA Bourges campus has 6 research platforms, each specialized in various fields such as electronics, materials and computer science. These infrastructures support innovation and collaboration between students, researchers and companies, thus strengthening the academic and industrial excellence of the institution.

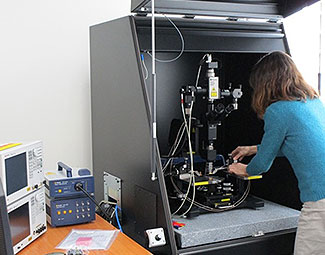

The PRISME laboratory’s Micro-Nano Robotics division has developed platforms to validate the methodological approaches and concepts studied in the design and control of microrobotic systems, particularly in the medical field.

Contact and/or non-contact micromanipulation platforms have been developed in collaboration with industrial partners for medical applications involving the targeted delivery of therapeutic vectors into confined biological environments of the human body (cochlea, eye, blood vessels and brain).

A contact micromanipulation system using AFM tips with 6 degrees of movement has been developed for manipulating and characterising biological and neuronal cells. A magnetic micromanipulation system with 5 degrees of freedom has also been developed to control medical microrobots. The latter is being used to deliver therapeutic vectors to cancerous tumours (see Figure 1 below).

The PRISME laboratory’s Vision, Robotics and AI team has robots equipped with vision systems such as WIFIBOT and UR5 robotic arms.

The team also develops applications based on vision and artificial intelligence.

PRISME laboratory’s “VESTA” fire test platform is a Next Generation (NexGen) burner for ISO 2685/FAA AC 20-135 fire tests, particularly on aerospace composite materials.

The test bench can be equipped with a range of fine instrumentation depending on the measurements required: loss of mass, radiative or total heat flux, front and rear face temperatures (using thermocouples and a thermal camera), gas sampling andGC/MS testing.

- The detonation platforms are used to experimentally simulate the detonation of gas charges and their effects, as well as the propagation of shock waves in confined or unconfined, obstructed or unobstructed environments. The transition from a gas charge to a pyrotechnic charge and the change of scale are applied.

- The deflagration platform is used to experimentally simulate industrial gas explosions (such as hydrogen) in a variety of scenarios: injection flow rate, site geometry, etc.

These applications have been recognised and validated by our industrial partners.

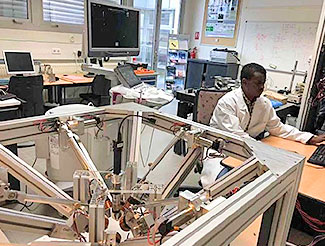

The LaMé Dynamics & Mechanics platforms: 2 test rooms for characterising the behaviour of materials:

- the first test room is dedicated to static tests and is equipped with an MTS electromechanical testing system and a set of 3 load cells (5 kN, 20 kN and 100 kN) and various Mohr devices, which can be used to perform tensile and compression tests, as well as 3 or 4-point flexural tests (conventional or on close supports). This equipment also includes:

- two high-resolution 28-megapixel cameras (Prosilica GX)

- a range of 35-200mm Nikkor lenses and telecentric lenses

- two digital image correlation software packages and one digital image stereo-correlation software package.

- the second test room is dedicated to transient dynamic testing and is equipped with 2 banks of interchangeable Split-Hopkinson pressure bars: steel, nylon and aluminium, allowing for the characterisation of the dynamic response and speed sensitivity of a wide range of materials. This equipment also includes:

- an ultra-fast acquisition and amplification chain

- an ultra high-speed camera (Photron SA5) and appropriate lighting

- laser displacement sensors

- a range of 35-200mm Nikkor lenses and telecentric lenses

- two digital image correlation software packages and one digital image stereo-correlation software package.

DARC/INSAnonym is a software platform for organising competitions of anonymisation and re-identification of personal data, in line with artificial intelligence or cybersecurity competitions. Anonymisation is a process defined by the General Data Protection Regulation (GDPR), which consists of publishing data in a way that minimises the risk of personal data being compromised. However, in order to prove that a dataset is anonymous, an analysis of the robustness of the anonymisation technique is required. The DARC/INSAnonym platform, developed by students at INSA Centre Val de Loire under the supervision of Prof. Benjamin Nguyen and in collaboration with researchers at INSA Lyon, Inria (the French Institute for Research in Computer Science and Automation) and the Université du Québec in Montréal, can be used to construct anonymised datasets so that teams of students or researchers can test and quantify their robustness through experimental re-identification in a controlled context. The development, expansion and dissemination of this platform will continue under the Interdisciplinary Project on Privacy (iPOP) Cybersecurity Priority Research Programme and Equipment (PEPR), with funding of around €500,000. The platform is designed for companies that want to test the robustness of their anonymisation techniques.